Hint: It Advances your Inventiveness

When we started BotFactory, we stuck with readily available conductive inks and avoided any risky research into printed electronics. After our successful Kickstarter and building up sales, we met a lot of people that wanted to print on Kapton or FR4, or print layers of insulation so one could print Multilayers. Naturally, we began to focus on that, and we’re really excited to tell you that we’ve reach the first goal of creating a highly conductive ink that allows you to print on FR4 and Kapton, as well as many non-porous or coated materials. Yes, I will repeat that. You can use our Advanced Inks to print on non-porous or coated materials. If you look around yourself right now, you can see a number of materials you could theoretically print on.

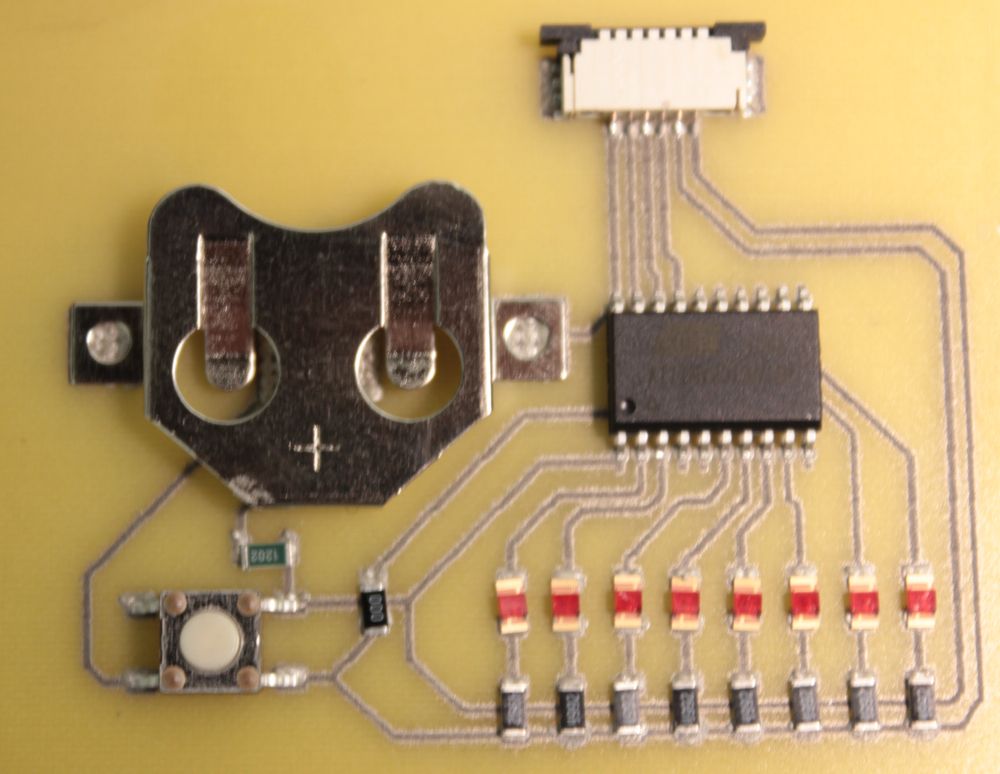

This is only the first step of many, and you can only print single-layer boards, but the possibilities available to you now are significantly larger. Here’s just a list of things you can make with our Advanced Inks:

LED Strips and Arrays

- Attached is a video demonstrating an LED array – theoretically we could make a 40x40 LED array on one Squink

Wearables

- Watches, Pulse-meters, EEG devices, devices that vibrate when a text is received, circuits that can be sown into fabrics,

‘Hidden’ Circuits

- The sheer ‘flatness’ of many PCBs is a great irritation to most product designers. With Squink you can design your circuit to fit into any area, finally providing much needed peace between your product designer and Electrical Engineer.

Custom Flexible Wire Harnesses

- Connecting sensors, power supplies and other components to each other over great distances is a problem when you have heavily articulated devices like a robotic arm. Disconnection is not an option – Squink gives you the chance to print those complex wire harness and avoid that problem.

What's Different

In addition, one can finally place through-hole components! Granted, you have to do the drilling yourself, but that doesn’t mean you should be limited to using SMD components from now on. We do recommend using conductive glue rather than soldering – the heat might damage the traces – and besides, our glue is very strong and durable. For SMD components, having a few holes to better fasten a component like a USB hub or a header is critical to making a great prototype.

The table below covers the expected electrical characteristics of a set of traces that were printed with three passes - you can print more passes to improve conductivity.

| Trace Width (20 mm length) | Max Recommended Amperage @ 5V |

| 10 mil (0.25 mm) 20 mil (0.5 mm) 30 mil (0.75 mm) 40 mil (1 mm) 50 mil (1.25 mm) 100 mil (2.5 mm) |

190 mA 450 mA 650 mA 950 mA 1.35 A 1.95 A |

This is the first step amongst many – and right off the bat Squink users get to play with our

advanced ink without having to buy a new machine. Buy now while supplies last!