Technology Readiness Levels (TRLs) and Manufacturing Readiness Levels (MRLs) are crucial metrics for assessing the maturity of emerging technologies like 3D printing. As we enter 2024, these scales provide valuable insights into the progress of additive manufacturing, including the rapidly evolving field of 3D printed circuit boards (PCBs). This blog post explores the current state of TRLs and MRLs in 3D printing, highlighting industry advancements and success stories that showcase the technology's growing capabilities and potential.

Readiness Level Definitions

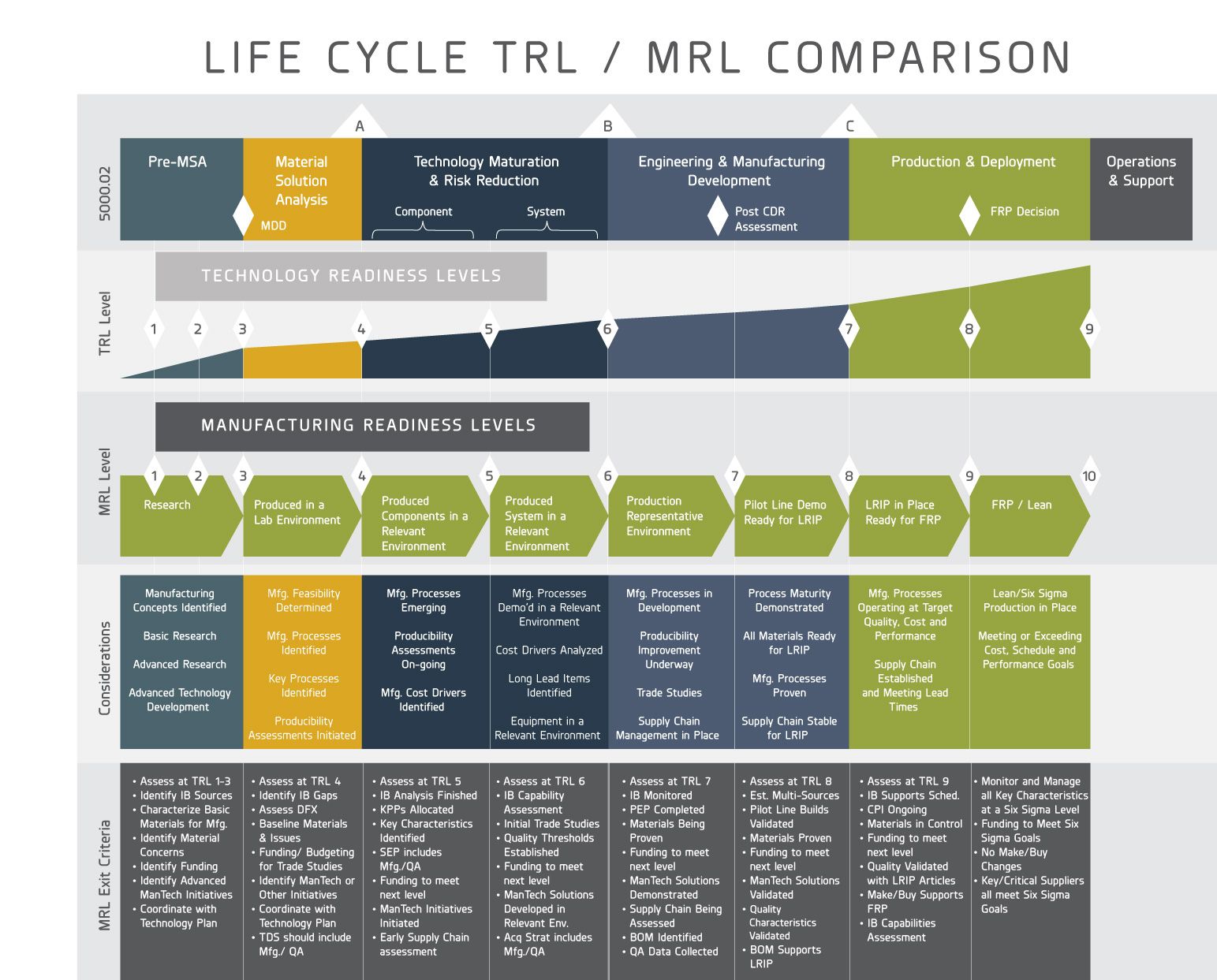

Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL) are standardized metrics used to assess the maturity of technologies and manufacturing processes. These scales help organizations evaluate the readiness of new technologies for deployment and production.TRL is a 9-point scale originally developed by NASA in the 1970s for space exploration technologies. It ranges from TRL 1 (basic principles observed) to TRL 9 (actual system proven through successful mission operations). The European Commission adopted TRL for EU-funded research and innovation projects in 2014. TRLs provide a common language for discussing technological maturity across different fields and help track development progress. Key TRL stages include:

- TRL 1-3: Basic research and proof-of-concept

- TRL 4-5: Technology development and validation in the laboratory

- TRL 6-7: Technology demonstration in relevant environments

- TRL 8-9: System completion, testing, and proven operation

- MRL 1-4: Basic manufacturing implications and concepts

- MRL 5-6: Manufacturing process development and capability demonstration

- MRL 7-8: Manufacturing process maturity and pilot line capability

- MRL 9-10: Low-rate production to full-rate production with lean practices

Both scales are crucial for risk management in technology development and acquisition. They help identify maturity shortfalls, associated costs, and risks. The "Valley of Death" in technology development, spanning TRL 4-7, represents a critical phase where many promising technologies fail to progress due to lack of investment. Using TRLs and MRLs together provides a more comprehensive view of a technology's overall readiness. While TRL focuses on the technology itself, MRL addresses the ability to produce it at scale, considering factors such as cost, materials availability, process capability, quality management, and workforce readiness. In the context of technology management, these scales facilitate communication between developers, program managers, and acquisition officials. They inform decision-making throughout the development lifecycle and support other assessments like cost estimates and risk evaluations (1)(2)(3)(4)(5).

The image below is a comprehensive comparison chart between Technology Readiness Levels (TRL) and Manufacturing Readiness Levels (MRL) across the life cycle of product development (6).

Current Readiness Levels in Additive Manufacturing

The 3D printing industry has made significant strides in recent years, with various technologies reaching different levels of maturity across the Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL) scales. As of 2024, the readiness levels for different 3D printing technologies and applications vary considerably. Metal additive manufacturing technologies, such as Powder Bed Fusion (PBF) processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), have generally reached high TRLs and MRLs (8-9) and are used in production environments for aerospace, automotive, and medical implant manufacturing. For example, GE Aviation's fuel nozzles for the LEAP engine, produced using metal 3D printing, have reached TRL 9 and MRL 9, demonstrating full-scale production capabilities.

Polymer 3D printing technologies, including Fused Deposition Modeling (FDM) and Stereolithography (SLA), have also achieved high readiness levels, with TRLs of 8-9 and MRLs of 7-8, and are widely used in prototyping, tooling, and some end-use part production. However, newer polymer 3D printing technologies like Multi Jet Fusion (MJF) and Carbon's Digital Light Synthesis (DLS) are at slightly lower readiness levels (TRLs 7-8 and MRLs 6-7) as they continue to mature. In contrast, 3D printed electronics and PCBs are at lower readiness levels (TRL 6-7 and MRL 5-6), indicating that while demonstrated, they are not yet fully mature for widespread commercial production. Emerging technologies in this field, like the ElectroUV3D printer from Chemcubed, are still proving their capabilities. Bioprinting technologies, involving the 3D printing of biological materials, are at even lower readiness levels (TRL 4-6 and MRL 3-5) and are primarily in the research and development phase. Large-scale 3D printing for construction and infrastructure applications also shows varying readiness levels, with some concrete 3D printing technologies reaching TRL 6-7 and MRL 5-6. The software ecosystem supporting 3D printing has evolved, with design tools and simulation software reaching high readiness levels (TRLs 8-9 and MRLs 7-8), pushing the boundaries of 3D printed electronics design (7)(8)(9).

3D Printed PCBs in 2024

| Aspect | Status in 2024 |

| Technology Readiness Level (TRL); Manufacturing Readiness Level (MRL) |

6-7, 5-6 |

| Key Advantages | Rapid prototyping, complex geometries, embedded components, recyclable and sustainable |

| Main Challenges | Conductivity, resolution, multi-layer complexity |

| Primary Applications | Prototyping, wearables, IoT devices, aerospace |

The current Technology Readiness Level (TRL) of 6-7 indicates that 3D printed PCB technology has been successfully demonstrated in relevant environments and is nearing system prototype demonstration in an operational setting. However, the slightly lower Manufacturing Readiness Level (MRL) of 5-6 suggests that while manufacturing processes are progressing, there are still challenges in scaling up production and ensuring consistent quality across larger volumes. This information was reported in the 2024 Annual Review of Electronics Manufacturing.

One of the most significant advancements in 3D printed PCBs has been the development of conductive materials that can achieve conductivity levels closer to traditional copper traces. Companies like BotFactory and Nano Dimension have introduced machines such as the SV2 and DragonFly IV, capable of producing multi-layer PCBs with high-performance electronic circuitry combining conductive and insulating inks. The SV2 further enhances functionality with its integrated solder paste and pick-and-place capabilities, although the DragonFly offers superior resolution. This technology enables the creation of PCBs with complex geometries and embedded components, opening up new design possibilities for electronics manufacturers.

The aerospace industry has shown particular interest in 3D printed PCBs due to the potential for weight reduction and customization. In 2024, several aerospace companies are exploring the use of 3D printed PCBs for satellite components and unmanned aerial vehicles, where the ability to create lightweight, complex structures is highly valuable. Despite these advancements, challenges remain. The resolution and precision of 3D printed PCBs are still not on par with traditional manufacturing methods for high-density interconnects. Additionally, ensuring consistent electrical performance across different prints and scaling up production for high-volume manufacturing are ongoing areas of development. Research institutions and companies are actively working to address these challenges. Efforts are focused on improving conductive materials, developing more precise printing techniques, and creating software tools that can optimize PCB designs for 3D printing. As these advancements continue, it is expected that the TRL and MRL of 3D printed PCBs will increase, potentially reaching levels 8-9 for specific applications in the coming years (3)(8)(10).

3D Printing Success Stories

In conclusion, while 3D printing and 3D printed electronics have made significant progress, as evidenced by their increasing TRLs and MRLs, there is still room for growth and improvement. The coming years will likely see further advancements in materials, processes, and applications, pushing these technologies towards higher readiness levels and wider industrial adoption.