BotFactory has been working on developing models and systems that would allow our 3D printers for PCBs to print high-performing electronics devices under human supervision, while using Machine Learning and automated measurement processes to minimize the need for this human interaction. The goal is to design a process that can produce consistent prints of the same circuit, with minimum deviation, and under a controlled set of performance parameters. This work is also known as "Automated 3d Printing using supervised machine learning".

Automated 3D printing using supervised machine learning is a cutting-edge technology that combines the benefits of automated 3D printing with the power of machine learning algorithms. In this process, machine learning algorithms are used to optimize the printing process and improve the quality of 3D printed circuits, while human operators oversee the process and make necessary adjustments.

The machine learning algorithm is trained using data collected during the printing process, such as sensor readings, printer settings, and material properties. It also uses the changes to the parameter made by a human to adjust the print. The algorithm uses this data to learn the relationships between the printing parameters and the quality of the printed object. With this knowledge, the algorithm can predict the optimal printing settings for a given object, thereby optimizing the printing process and improving the quality of the printed object.

One significant advantage of automated 3D printing using supervised machine learning is its ability to optimize the printing process to reduce the need for manual adjustments. With the algorithm in place, the printing process can be automated to a large extent, with the machine making adjustments based on the predicted optimal settings and the feedback provided by the user. This can help reduce the time and effort required for printing and minimize the potential for human error.

Another benefit of automated 3D printing using supervised machine learning is the ability to improve the quality of 3D printed pcbs. The algorithm can predict the optimal printing settings for a given object, taking into account factors such as layer thickness, material properties, material ageing and print speed. This can help produce 3D printed circuits that have consistent electrical properties, smoother surfaces, improved structural integrity, and better accuracy.

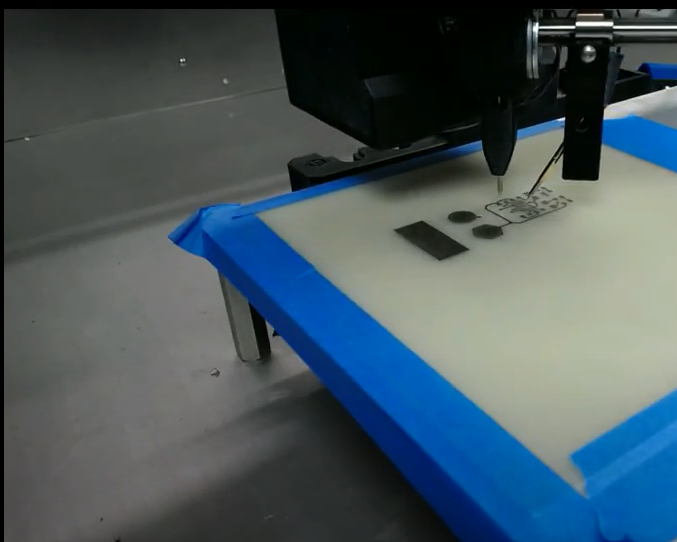

Image: BotFactory Printer measuring traces after printing a conductive layer

Furthermore, automated 3D printing using supervised machine learning can help BotFactory in reducing waste and lower production costs. By optimizing the printing process, the algorithm can adapt to materials at different stages of ageing, or under varied environmental conditions, hence extending the useful life of the material, resulting in a lower environmental impact. Additionally, by improving the quality of the printed objects, fewer circuits will need to be discarded due to defects, resulting in lower production costs.

However, it is important to note that automated 3D printing using supervised machine learning still requires human supervision. While the machine learning algorithm can predict optimal settings, it cannot replace the human decision-making process. The human operator must still oversee the process and make necessary adjustments based on their expertise and knowledge. The process may evolve into a more autonomous system once enough training has taken place, but there's plenty of work ahead of us.

In conclusion, automated 3D printing using supervised machine learning is an exciting development in the field of additive manufacturing of electronics. By combining the power of machine learning with human expertise, this technology can optimize the printing process, improve the quality of printed circuits, and reduce waste and production costs. As the technology continues to evolve, it is likely to become an increasingly important tool in the manufacturing industry, and BotFactory Printers are likely to pioneer this new wave of advance manufacturing systems for electronics devices.