Over the course of about 12 months, from May 2019 to 2020, our technology has continuously evolved. New features and fixes included changes and additions to both the hardware and software, making the user interface (UI) and production process progressively easier to learn and use.

One of the major features SV2 gained was a connectivity update. This update was released in early May of 2019 after hearing feedback from customers that some had difficulties connecting to their printers. In the new “Easy Connect Mode” SV2 creates a Wi-Fi access point and runs an Ethernet DHCP server, so the user can easily connect directly to the printer—this mode will keep the printer off the network for security sensitive environments.

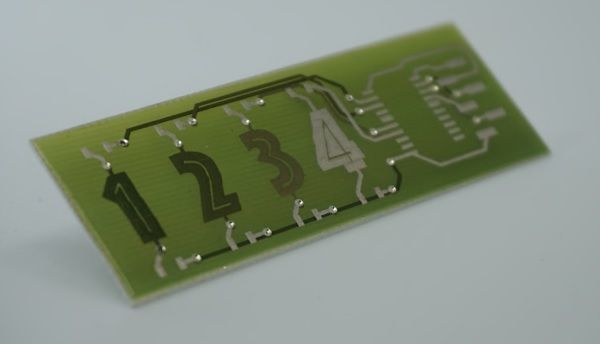

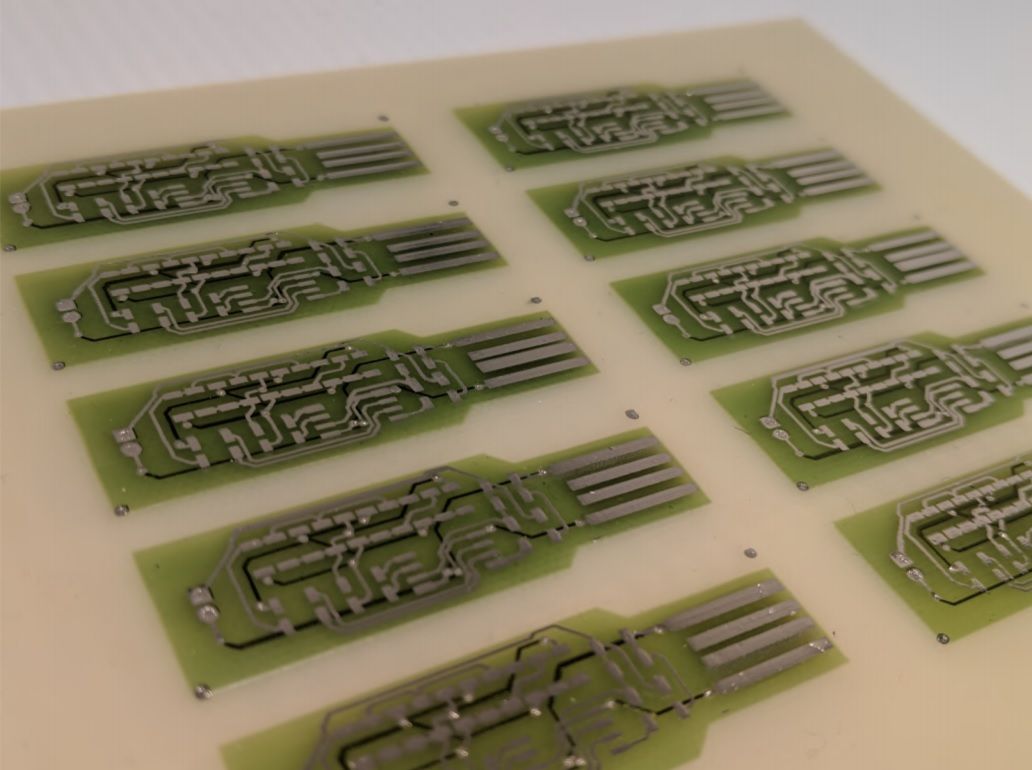

Our software guides the user through printing one and two layer designs. However, two layer printing is not enough for complex circuits, so we released an update that made printing beyond two layers possible in mid-October in 2019. This update added an option to upload 4-layer designs, allowing users to create more robust and complex projects. More layers means easier routing for smaller designs and the possibility to use ground and signal layers. This substantial capability upgrade is fitting as technology progresses to become more compact while still being required to perform its intended tasks.

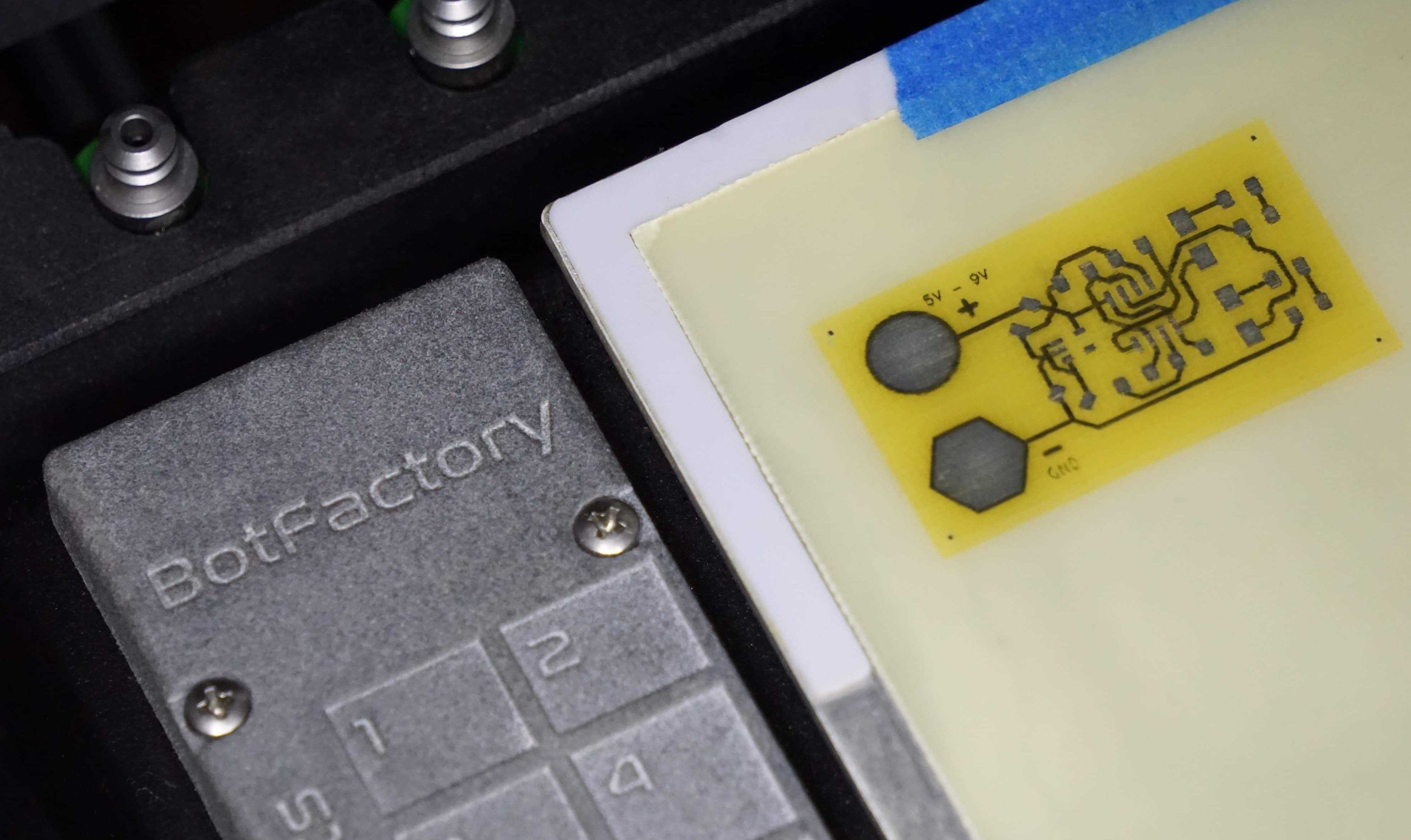

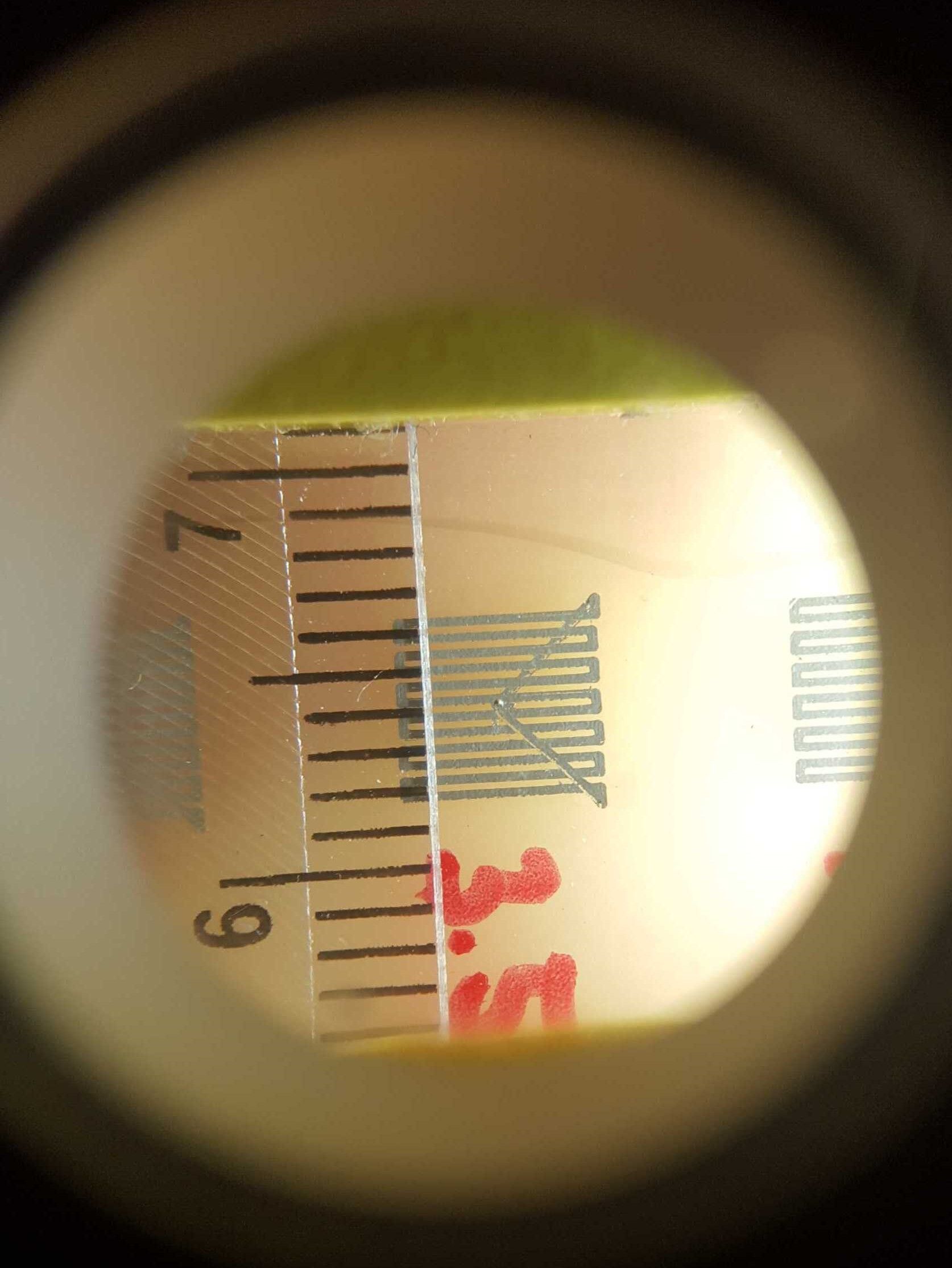

Board alignment is an important step of any PCB manufacturing process. Previously, our machines printed a small cross at the top corner of each print. These were used to align the Paste head and PnP head, but ultimately took away about 10mm x 10mm from the work area. The cross method, while effective, aligns to a single point and only provides enough information to correct offsets. We completely changed this process to instead use two fiducials of the designer’s choice to align the board. Having two points, the fiducial method, provides enough information to correct both offsets and rotation. Allowing users to select the fiducial also lets them place it in empty areas of their design rather than outside their board. Since fiducials are an industry standard, we can use externally manufactured boards for gluing, picking-and-placing, and assembly, while the BotFactory software takes care of any rotational errors introduced during the board placement.

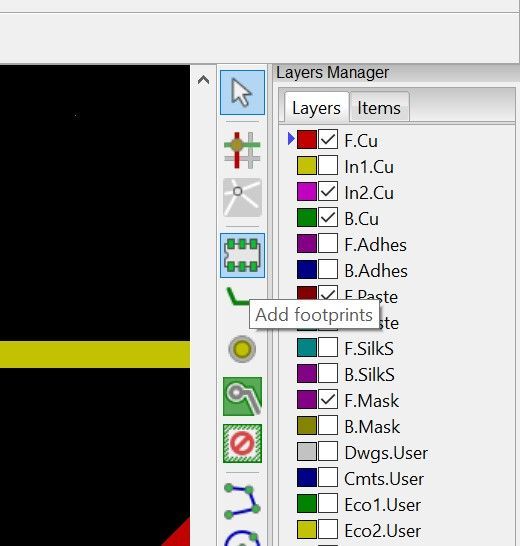

Who wants to enter footprint information for every design? Or between multiple printers? We certainly didn’t so we added a new footprint manager. This feature, which includes some pre-loaded standard footprints, lets users import and or export footprints as well as manage the footprints that have previously been defined and remembered.

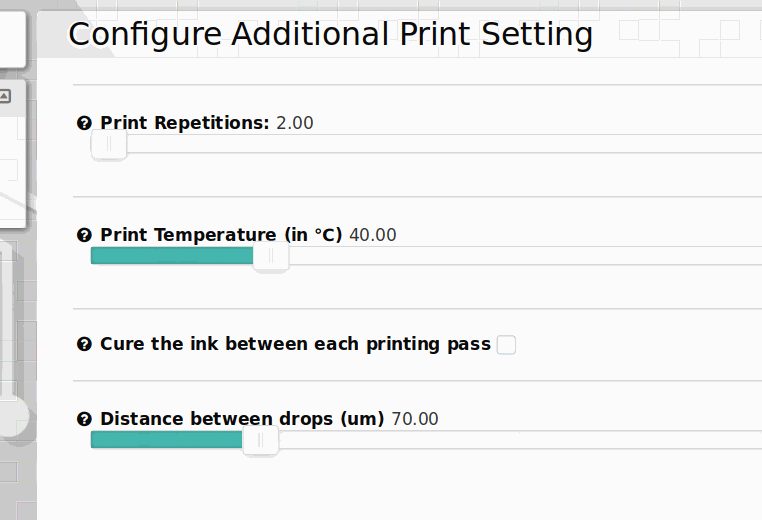

Just because you’re printing on a flexible substrate doesn’t mean you want it to flex while you’re printing. We noticed that printing on some substrates would cause them to warp due to heat, so after substantial adjustment and testing, we found a better temperature that would improve the performance of our new ink formulations. A slider was added and fine-tuned to control the temperature applied to the substrate during printing to improve adhesion and ink wetting.

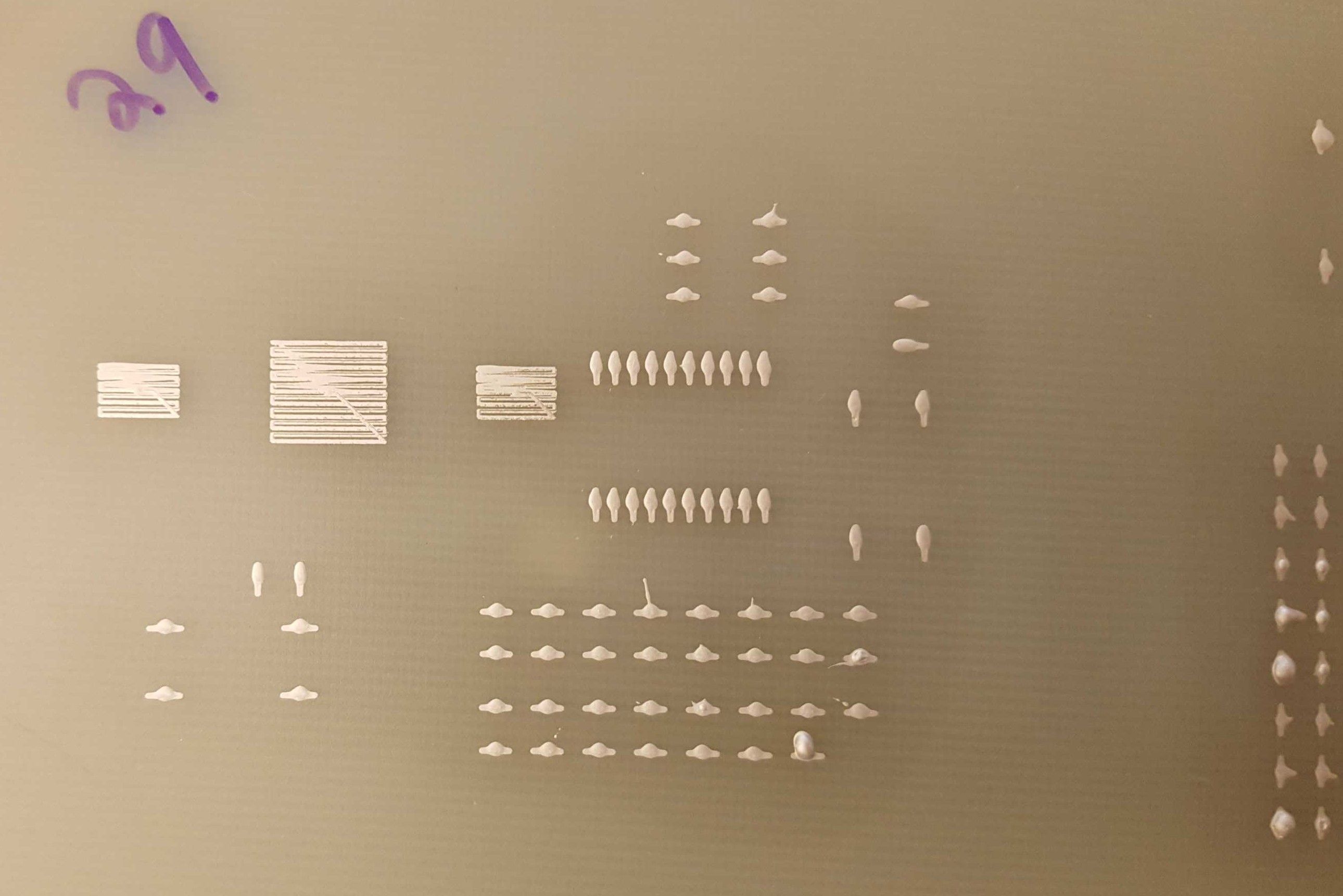

Our pasting process was a bit like one of those dot-matrix printers. It worked but you could still see all the dots. With the updated hardware we decided to revamp the pasting software as well.

Instead of pasting a grid of dots, SV2 now extrudes continuous lines of paste. The pasting process also auto-calibrates the height before gluing.

As of August 2020, SV2 now allows users to configure the distance between ink drops during printing. We've also improved printing configurations for both insulating and conductive inks to achieve better resolutions.

While SV2 gained substantial software updates, it also received a well worth mentioning material change. As of April 2020 our conductive ink can now be soldered onto. This isn’t mentioned in our Change Log, since it isn’t a software change, but soldering, for the longest time, was one of our top requests and it has finally been met!

While only a few main features were mentioned, there were many more improvements and bug fixes for each of them. Some of these bug fixes include reducing overprinting that made lines wider than desired, fixing issues regarding offline updates, configurable curing jobs, helpful animations, and more. All of the progress and updates can be found in our Change Log. You can expect more updates regularly, as we are constantly working to improve our machines to provide simple, customizable, and quality printing to our users.

Share Your Experience With Us!

We'd love to hear about your experiences, features that you need, and how you're working around them today.