Introduction

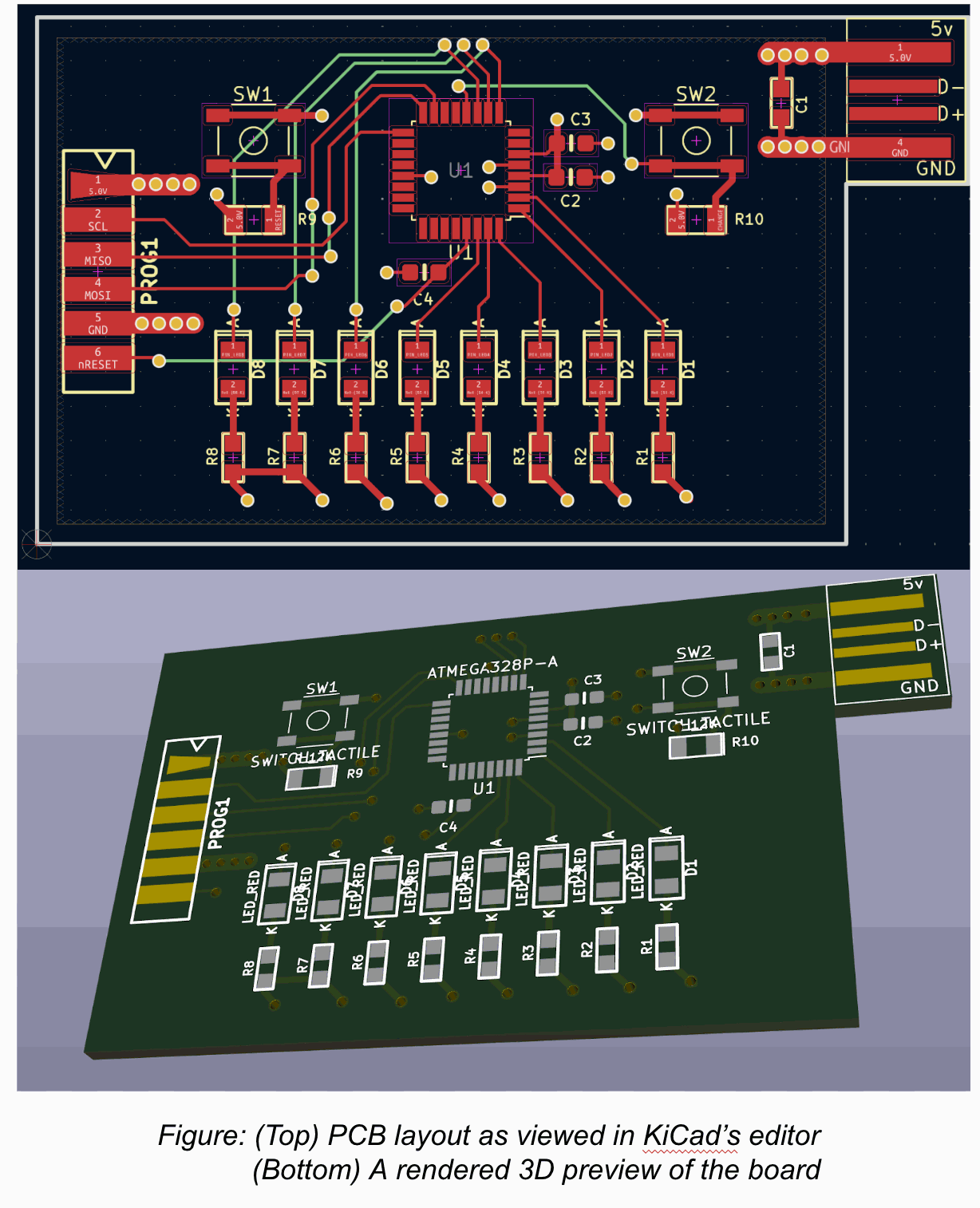

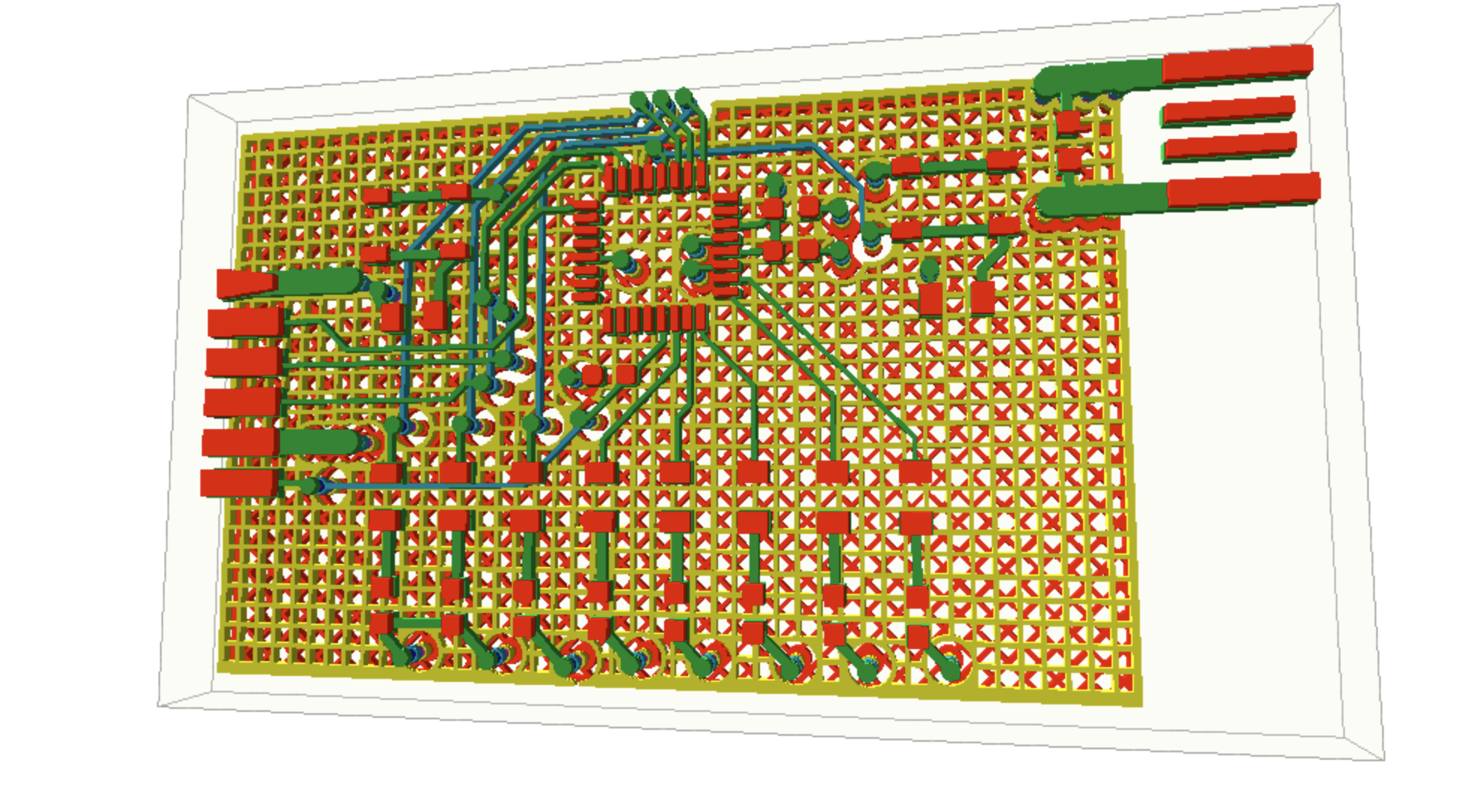

The classic Larson scanner effect—an LED array sweeping back and forth—has long been a favourite among electronics enthusiasts. Our previous project showcased how to print and assemble a simple two-layer Larson scanner PCB with the BotFactory SV2. Now, we’re taking it up a notch. The new design moves from a two-layer board to a four-layer stack swaps out the microcontroller for an Atmega328P-AU, and implements a host of improvements that push the boundaries of what you can achieve in-house.

Why Upgrade?

Our original design worked perfectly for a straightforward LED sequence. But as soon as we started imagining more features—additional sensors, more robust firmware, tighter routing, and improved signal integrity—we knew we needed more layers and a more capable microcontroller. The Atmega328P-AU, with its greater I/O and memory capabilities, gives us room to expand our code and add complexity. The four-layer PCB stack provides dedicated planes for ground and power, reducing noise and interference while making routing more efficient and flexible.