Thermal inkjet and piezoelectric inkjet technologies are two leading methods for precision printing in electronics manufacturing, each offering unique advantages for applications like printed circuit board (PCB) production. As reported by Power Electronics News, these technologies differ significantly in their operating principles, with thermal inkjet using heat to eject ink droplets and piezoelectric inkjet employing electrically induced crystal deformation to force out ink.

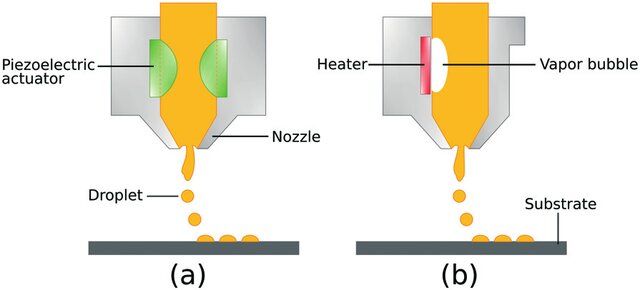

Fig: Schematic illustration of drop-on-demand inkjet printing process: (a) piezoelectric DOD mode and (b) thermal DOD mode (5).

Fig: Schematic illustration of drop-on-demand inkjet printing process: (a) piezoelectric DOD mode and (b) thermal DOD mode (5).Thermal Inkjet Technology

Thermal inkjet technology, also known as bubble jet, operates by rapidly heating a small resistor element to vaporize ink, creating a bubble that expands to eject a droplet through the nozzle. This process occurs in microseconds, allowing for high-frequency operation and fast printing speeds (1)(2).

Fig: The HP45 printhead is an inkjet printer cartridge designed by Hewlett-Packard. It is found in inkjet printers and plotters from the early 2000’s (6).

The technology is limited primarily to water-based inks, as the heating process requires specific fluid properties (2) This constraint can be advantageous in some PCB applications, as water-based inks are often preferred for their environmental friendliness and ease of handling. Thermal printheads typically achieve resolutions up to 1200 dpi, which is sufficient for many PCB manufacturing processes (3). One unique advantage of thermal inkjet in electronics manufacturing is its compatibility with HP's Latex inks, which contain heat-activated polymers suspended in water (4). These inks offer improved durability and outdoor resistance compared to traditional water-based formulations, expanding the potential applications in PCB and electronics production. However, the heat-based ejection mechanism does lead to faster wear of the printhead components, resulting in a shorter lifespan compared to piezoelectric alternatives (1). This necessitates more frequent replacements, which is offset by the lower cost of thermal printhead units.

Piezoelectric Inkjet Technology

Piezoelectric inkjet technology utilizes the piezoelectric effect to eject ink droplets, offering precise control and versatility in printing applications. This method employs a piezoelectric crystal or ceramic that deforms when an electrical voltage is applied, creating pressure waves that force ink through the nozzle(1)(2). Key features of piezoelectric inkjet technology include:

- Long printhead lifespan due to reduced thermal stress

- Compatibility with a wide range of ink types, including solvent-based and UV-curable inks

- High precision droplet control, allowing for variable drop sizes (greyscale printing)

- Superior resolution capabilities, reaching up to 2880 dpi (1)

- Printing fine conductive traces and complex circuit patterns

- Depositing specialized coatings and materials

- Applying precise amounts of adhesives or solder paste

- Creating high-resolution solder masks and legend prints

Fig: An industrial inkjet printhead. The Xaar 1003 has 1000 active nozzles in 2 rows (7).

The piezoelectric mechanism allows for greater flexibility in ink formulations, as it does not rely on heat or require aqueous inks to eject droplets. This enables the use of functional inks containing conductive materials, nanoparticles, or other additives, making it crucial for advanced PCB production (2)(3).

Additionally, piezoelectric printheads can vary the size of droplets produced from the same nozzle, a process known as greyscale printing. By adjusting the size of each droplet, the printer achieves precise control over ink deposition. In some cases, smaller droplets can even merge in mid-air to form larger droplets. This capability is particularly valuable in PCB production, where creating gradient thicknesses or adjusting conductivity in traces is critical (4). One significant advantage of piezoelectric technology in electronics manufacturing is its ability to handle challenging fluids such as electro-conductive inks, large-particle opaque white and metallic inks, and even some 3D printing materials. This versatility makes piezoelectric printheads ideal for advanced PCB production techniques and emerging additive manufacturing processes in electronics.

However, piezoelectric printheads are generally more expensive to produce than thermal alternatives due to their complex construction. They also require more sophisticated drive electronics to control the precise voltage waveforms needed for optimal droplet formation (2). Despite these higher initial costs, the extended lifespan and versatility of piezoelectric printheads often make them a cost-effective choice for high-precision, high-volume PCB production environments.

Applications in PCB Printing

Inkjet printing technologies have transformed PCB production by providing precision, flexibility, and cost-effectiveness. Here's a comparison of thermal and piezoelectric inkjet technologies in PCB manufacturing:

| Application | Thermal Inkjet | Piezoelectric Inkjet |

| Conductive Traces | Suitable for wider, less complex patterns | Excels in fine, intricate patterns |

| Solder Mask | Effective for standard application | Superior for high-resolution deposition |

| Adhesive Deposition | Suitable for general application | Precise control for specialized adhesives |

| Functional Inks | Limited to water-based and Latex inks | Wide range of functional inks |

Thermal inkjet is ideal for rapid prototyping and high-volume production of standard PCBs, particularly with water-based inks for solder masks and basic legends. Its high firing frequencies (up to 15000 Hz) facilitate fast production cycles. Piezoelectric inkjet excels in precision-demanding applications, creating intricate conductive traces essential for advanced PCB designs. It's crucial in flexible electronics due to precise ink deposition control. Its compatibility with diverse functional inks enables multi-layer PCBs and advanced components.

Comparative Analysis

When comparing piezoelectric and thermal inkjet technologies for PCB manufacturing, several key factors come into play:

- Print Quality and Resolution: Piezoelectric printheads generally offer superior resolution, with capabilities up to 2880 dpi compared to thermal inkjet's typical maximum of 1200 dpi (4). This higher resolution allows for more precise deposition of conductive traces and finer details in PCB designs.

- Ink Compatibility: Piezoelectric printheads have a significant advantage in ink versatility. They can handle a wide range of inks, including solvent-based, UV-curable, and even challenging fluids like electro-conductive inks and large-particle metallic inks. This versatility is crucial for advanced PCB manufacturing processes. Thermal inkjet, while more limited, excels with water-based inks and HP's specialized Latex inks, which offer good durability for certain applications.

- Durability and Lifespan: Piezoelectric printheads generally have a longer lifespan due to less thermal stress. They are designed to last for the lifetime of the printer, barring external damage or blockages. Thermal printheads, subject to more wear from the heating and cooling cycles, typically require more frequent replacement.

- Cost Considerations: Thermal inkjet technology tends to be more cost-effective upfront due to simpler design and lower manufacturing costs. However, the longer lifespan of piezoelectric printheads can offset their higher initial cost in long-term industrial applications like PCB manufacturing.

- Printing Speed: Thermal inkjet can achieve very high frequencies, up to 15000 Hz, allowing for rapid printing speeds. While not all piezoelectric printheads can match this frequency, their ability to produce variable drop sizes can lead to more efficient ink usage and potentially faster overall production times for complex PCBs.

- Precision and Control: Piezoelectric technology offers superior control over droplet formation, allowing for variable drop sizes from a single nozzle (greyscale printing). This precision is particularly valuable in PCB manufacturing for creating gradient thicknesses or varying conductivity in traces.

- Environmental Considerations: Thermal inkjet's compatibility with water-based inks can be an advantage in environments prioritizing eco-friendly manufacturing processes. However, piezoelectric's ability to work with a broader range of inks allows for more specialized, environmentally-conscious formulations when required.

- Maintenance: Thermal printheads have a self-cleaning capability due to the bubble formation process, which can be advantageous in maintaining consistent print quality. Piezoelectric printheads, while generally more durable, may require more sophisticated maintenance procedures to prevent clogging, especially when using specialized inks.

In PCB manufacturing, the choice between these technologies often depends on the specific requirements of the application. Thermal inkjet may be preferred for high-volume production of standard PCBs, especially where cost is a primary concern. Piezoelectric technology, with its precision and versatility, is often the choice for high-end, complex PCB designs requiring fine details and specialized materials (1)(2)(4).