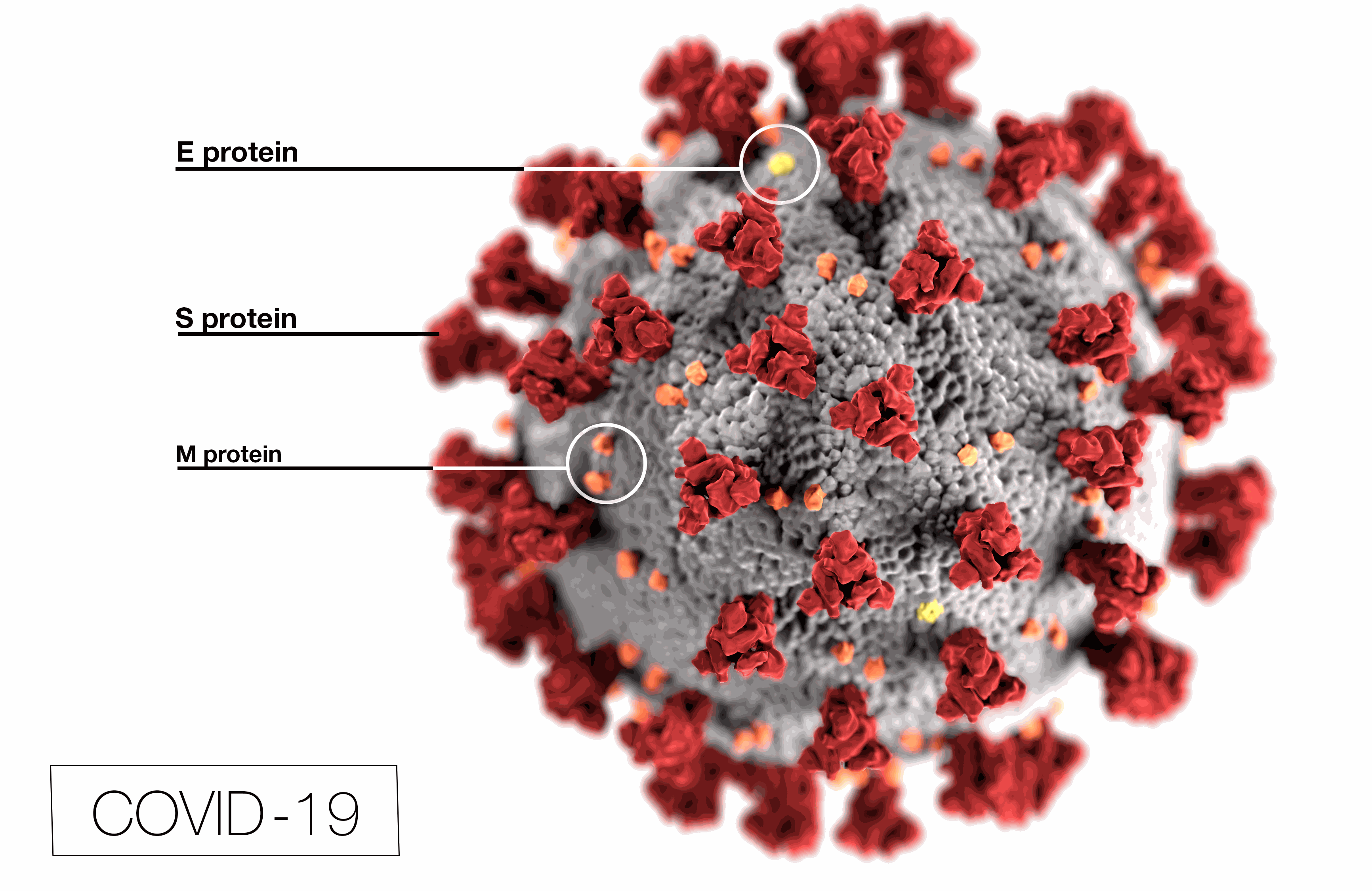

The changing workforce amidst the COVID-19 pandemic.

Amidst uncertain times caused by COVID-19, companies are enacting new policies to safeguard their workforce and communities. The high population density and inherent risk posed in such circumstances by urban environments have forced many companies to shift their workers from traditional office roles to Work From Home (WFH) roles. While COVID-19 has mostly impacted large urban spaces, entire states have declared aggressive shelter-in-place policies to help curb the number of infected individuals. These policies are pushing companies to evolve and adopt new tools that allow productivity to be maximized from the home of their employees. BotFactory's SV2 is an example of a tool that is enabling engineers with HomeLabs. The changing workforce needs new tools.

Image Credit: Alissa Eckert,MS; Dan Higgins, MAMS; CDC

COVID-19's Impact on Research and Engineering

How Companies are Reacting to the Pandemic

From Traditional Roles to Working from Home.

According to a study done by Gallup in 2016, roughly 43% of Americans work remotely with some frequency, and another study in 2018 by Global Workplace Analytics found that roughly 3.6% of the workforce have roles that allow them to work from home half of the time. As the integration of cloud based systems has gained popularity, most workers in the technology and engineering sector are able to work independently and collaboratively with ease. With state mandated work from home policies, use of these cloud based systems has increased the ability of engineers to work from home, while decreasing overall productivity loss.

“Project staff can meet virtually, share documents and discuss specific details” says Michael Tobias, founder and principal of New York Engineers, an MEP consulting firm located in New York City. There is one thing, however, that engineers are not capable of doing from home: manufacturing and prototyping their projects. Engineers can utilize the tools they have access to from home to collaborate with other engineers but unfortunately they lack the ability to build, test, and refine their designs. Consequently, engineers working remotely can only push their projects to the design stage and their work is therefore limited in scope by the tools available to them rather than their talent and ingenuity.

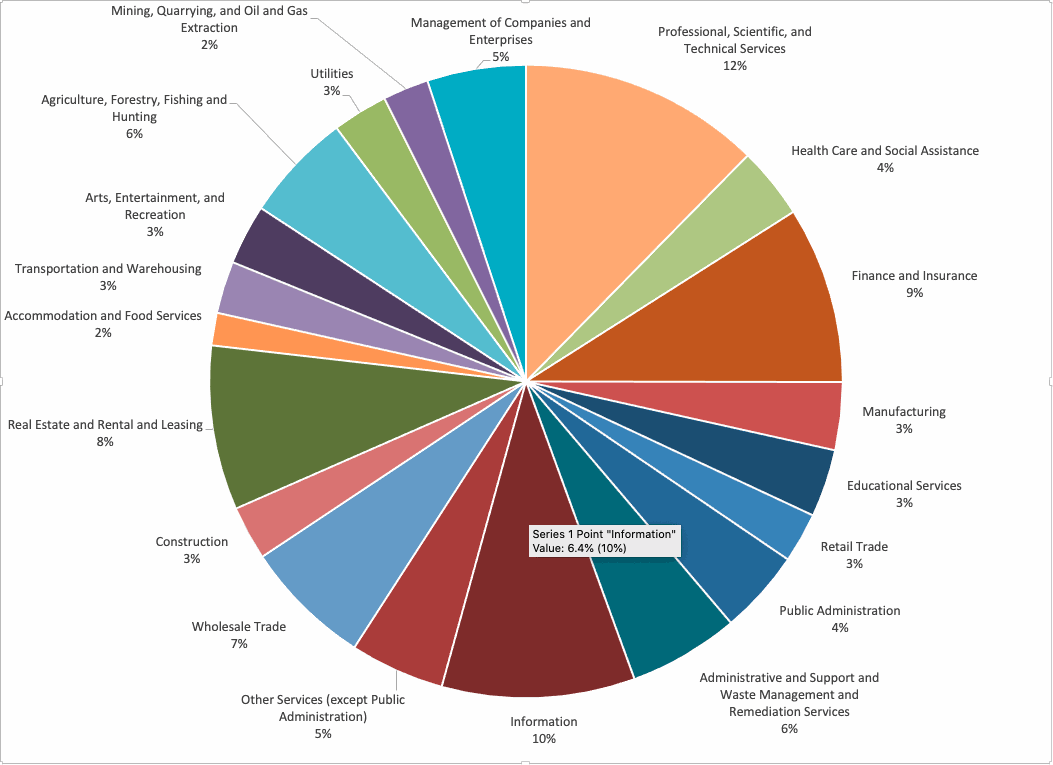

Graph illustrates the percentage of people who work from home by industry.

Graph courtesy of Global Workplace Analytics

COVID-19 has affected all swathes of society, including large public institutions dedicated to research, causing them to wind down research activities and even shutting them down entirely. While such large institutions are capable of either reducing or shutting down their research efforts for a time, not everyone can do so and remain financially viable, especially smaller and less well-funded organizations. This problem is compounded by the majority of non-COVID-19 related research being shut down entirely leading to a large pool of talent and equipment sitting idle. Understandably, most research centers are driving all exploration efforts to combat respiratory infections, with institutions like Johns Hopkins University shifting the majority of their resources to COVID-19 with the main efforts highlighted in their COVID-19 Research Response Program Area. The main efforts of their research efforts seem to be going to diagnostics, health worker protection, host pathogenesis, medical supply innovation (to ease the shortage of medical equipment, primarily ventilators), and viral genetics. Johns Hopkins University and the University of Washington are some of the top federally funded research institutions in the country, boasting ranks in the top 5 of the most federally funded research institutions in fiscal year 2017.

Unfortunately for the researchers whose work is not considered essential at this time, this causes significant delays in their progress, frustrating both them as well as their financers, be they federal organizations or private ones. Researchers whose work does not directly benefit the efforts against COVID-19 are forced to work from home, by carrying out data analysis, reviewing literature, writing proposals and progress reports. Researchers as well as R&D engineers suffer from the lack of equipment at home to fully utilize their time and talents.

The COVID-19 pandemic has dramatically shifted our worldview and highlighted issues that many businesses are still grappling with in order to be viable. Most businesses lack the tools needed to shift a large amount of their workforce into work from home roles, causing them to face significant financial dilemmas. Companies that were able to quickly transition their workforce to work remotely ahead of the shelter-in-place orders were not as heavily impacted as those who delayed until the policies were officially announced. With the growing interconnectedness of the world, cloud based systems greatly help in allowing engineers and research scientists to communicate and organize effectively. Cloud based systems allow for the seamless transition of designs from concepts to a fully fleshed out design, but unfortunately not beyond that.

Engineers in work from home roles are pushing their concepts to the final design stage but they are seemingly stuck in this step of the development cycle. Electrical engineers are unable to get their Printed Circuit Boards (PCBs) manufactured due to the pandemic and are unable to iterate and finalize their design. For mechanical engineers this seems like a perfect use case for 3D printers which allow the engineer to iterate their ideas and work out the problems before finalizing the design for manufacturing. Fortunately for most mechanical engineers 3D printers are readily available and accessible. The same cannot be said about electrical/electronics engineers who generally require a good amount of external resources to finalize their design, at least until now.

The BotFactory SV2

Seamless PCB Manufacturing From Your Desktop

Manufacture PCBs directly on your desktop using the BotfFactory Sv2. Utilizing patented inkjet technologies the SV2 uses Gerber files generated by CAD software to manufacture PCBs that can be used to test and iterate designs.

The SV2 is essentially what the 3D printer is to the mechanical engineer but for the electrical/electronics engineer. The SV2 allows electrical and electronics engineers to fully work from home. They are able to finalize their design through small scale in-home manufacturing of PCBs. The SV2 utilizes Gerber files generated by Computer Aided Design (CAD) programs to manufacture boards with up to four layers using a patented inkjet method. This allows for the design to be refined and pushed to the final design stage, eventually being pushed along into the manufacturing cycle. The SV2's in-home PCB manufacturing ability allows engineers in work from home roles to become fully operational and productive. BotFactory's HomeLab lets you convert your home into an electronics labs!